- Parameter

- Related products

Parameter

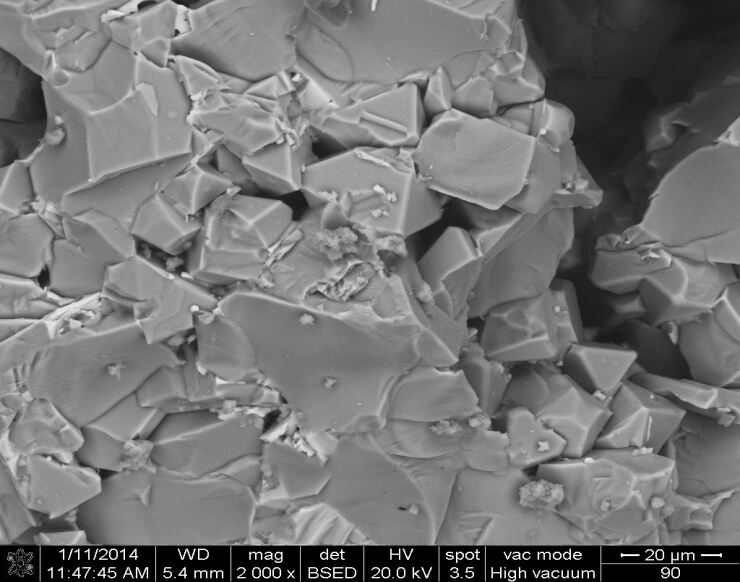

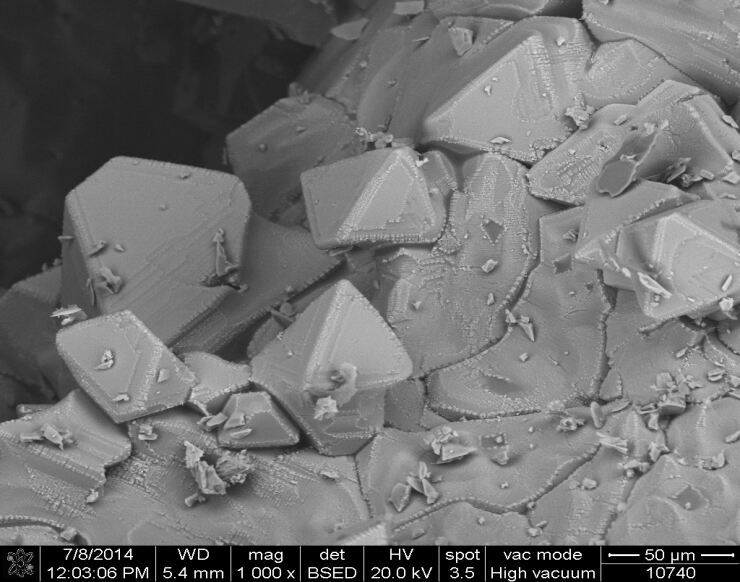

The "Jun brand high-pure fused alumina magnesia spinel use high -pure magnesia and industrial alumina smelting by large high -temperature electric arc furnaces. lt has high density, high refractory resistance, and good hightemperature volume stability, anti alkaline slag erosion and permeability, good thermal stability and other characteristics. lt is widely used for steelmaking electric furnace top, converter, ladle and porous plug brick/ladle well block, RH spinel brick/back lining castable, tundish current stabilizer & impacting plate board,transition zone of large cement rotary kiln & burnning zone, smelting alloy and glass heat storage rooms, lithium battery saggar and special plasma spray coatings.

Introducing alumina -magnesia spinels in refractory castable can significantly improve the liquidity, anti -penetration, anti-erosion and anti -peeling performance of castables. In particular, it can improve the ability of anti-wash against, improve the working life, reduce the refractory material required for production per ton of steel. Also solve the problem of cracking of materials caused by adding magnesia raw materials.

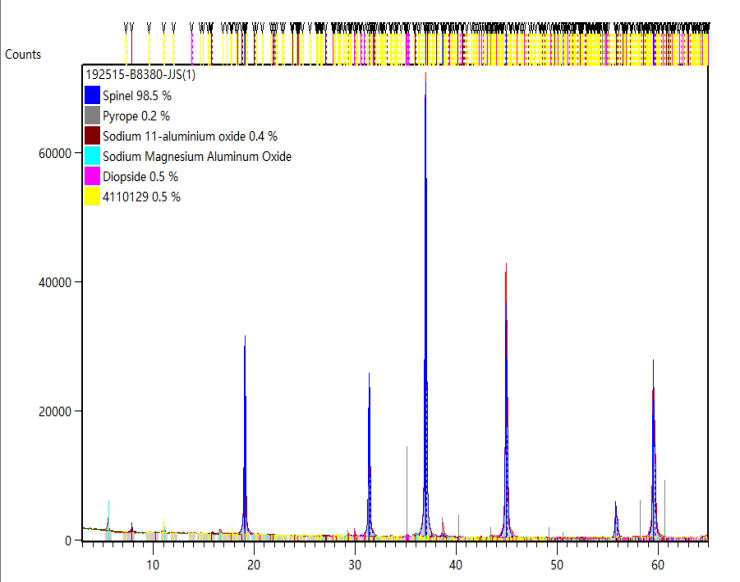

Physical Properties and Chemical Composition

| Item/Composition | Al₂O₃ | MgO | CaO | SiO₂ | Fe₂O₃ | Na₂O | Bulk density(g/cm) |

| AM-65 | 64~66 | 33~35 | ≤0.65 | ≤0.50 | ≤0.40 | ≤0.30 | ≥3.3 |

| AM-70 | 74~76 | 23~25 | ≤0.55 | ≤0.40 | ≤0.40 | ≤0.30 | ≥3.2 |

| AM-90 | 87~90 | 9~12 | ≤0.30 | ≤0.25 | ≤0.30 | ≤0.40 | ≥3.3 |

| Particle size | 0~0.2~0.5~1~2~3~5~8mm,100 mesh、200 mesh、325 mesh、5μm | ||||||

| Inspection stndard | GB5069-2001 | ||||||

| Packing | Inner plastic and external weaving 25KG/bag(can be customized according to customer requirements)) | ||||||

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ