Ever heard of calcined bauxite? A very special type of rock you use in many important things! In this text we examining following points: What is calcined bauxite?, How it is manufactured?, and Last but not Least how do we use calicned in day to day life? You also noticed that this rock is an important part of various industries, although you might have never heard about it.

Bauxite is a mineral that forms rock, known as calcined bauxite. Bauxite is native to the ground and therefore it undergoes a somewhat bizarre transformation. When the temperature is increased significantly, bauxite changes. This process makes the rock extremely hard and durable. It is exremely heat capacity and this property makes very useful in a variety of applications!

One major use of calcined bauxite is in the manufacture of two main products, abrasives and refractories. Abrasives are the specific materials used to smooth or shape a surface. They're like sandpaper, If you wanna smoothen things. In contrast, refractories are materials that withstand extremely high temperatures without degrading. Calcined bauxite is suitable to perform very well for these jobs as it has high strength and heat resistant without any issues.

Calcined bauxite is also an important raw material of refractory, it can be used to make brick and the proportioning other than fire clay. It could be used in place of other types of rocks, such as gravel or sand, for concrete production. Concrete is a very hard and strong material used to create buildings,Walkway,you can often see bridges. It is also made by combination with an aggregate (such as calcined bauxite) in a mixture of cement and water. Calcined bauxite is strong and has a long shelf life, making it popular among builders.

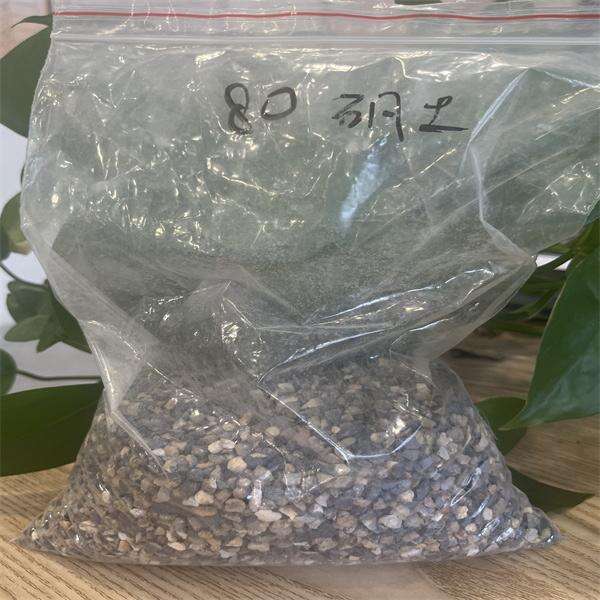

Now, how do we produce our calcined bauxite? The setup is really quite intriguing and not difficult. How Bauxite Is ProducedBauxite is first taken from the earth, where mines. Then, it is shredded into small pieces to be handled more easily. After that, the crushed bauxite is subjected to temperatures in excess of about 1600 degrees Celsius.

Firstly, the main content of your calcined bauxite is SiO2 and in other words silicon dioxide which means it really hard that will be used as abrasives. This hardness allows it to cut through many other materials, very easily, which is why garnet abrasives are so widely used in tasks such as sanding or polishing surfaces into great shiny smooth items.

In the construction field, calcined bauxite is used as an aggregate of concrete. Builders know that when they mix up concrete, it needs a little backbone. The another type of the thing to be note is, Calcined bauxite, cement and water are used in making concrete which have excellent strength properties. Simpson is very popular with build because it lasts a really long time as well and is quite durable which makes the material ideal for extensive construction endeavors.

We provide high-grade raw materials, a variety of calcined bauxite, and services, while growing together with our customers. While at the same time. Datong Company wants to create an all-win-win partnership with its partners in order for it to be able to serve customers better and offer them quality products.

Datong is a highly-tech national company that has been able to pass the ls0900l quality certification system and also the is014001 certificate for the environmental management system as well as the calcined bauxite accreditation for occupational health and safety. It was first listed on the 7th of April 2016 under the stock code 836236. Nowadays, it has become the largest and most comprehensive quality aluminum-based refractory raw base. Each tank is scrutinized with hydraulic test, radiography test, and air tight test, etc. The most sophisticated production equipment in the world assure strict quality control at each stage of production. We pay attention to every detail, and each small action is an integral part of our workforce.

Kaifeng Datong Refractories Co., Ltd was created in the year 2008 and is a high-tech calcined bauxite private enterprise in Henan Province, that is specialized in the production, development and sales of high-quality Refractory raw materials as well as related products. After years of development that has never stopped the company now has an annual output of 30.000 tons of high temperature alumina powder 20.000 tons of magnesium aluminum spinel (electric melting melting and sintering) 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina tabular alumina, 8, 000 tons of non-crystalline calcium Aluminate, thirty-three tons of high aluminum cement, and 50, 000 tons of different products that can be castable and shaped.

Datong invested 10 million dollars and constructed a chemical analysis lab and a micro-powder testing room, calcined bauxite, application laboratory high temperature laboratory pilot base, and over 40 sets of various testing equipments, including SEM energy thermometer XRD laser particle size analyzer, and other top testing and analysis equipment. The technical center employs over 10 technical employees with 1 senior engineer and 2 engineers. It maintains a closely working relationships with Wuhan University of Science and Technology Sinosteel Luoyang Institute of research in refractories, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of Refractory.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog