- Parameter

- Related products

Parameter

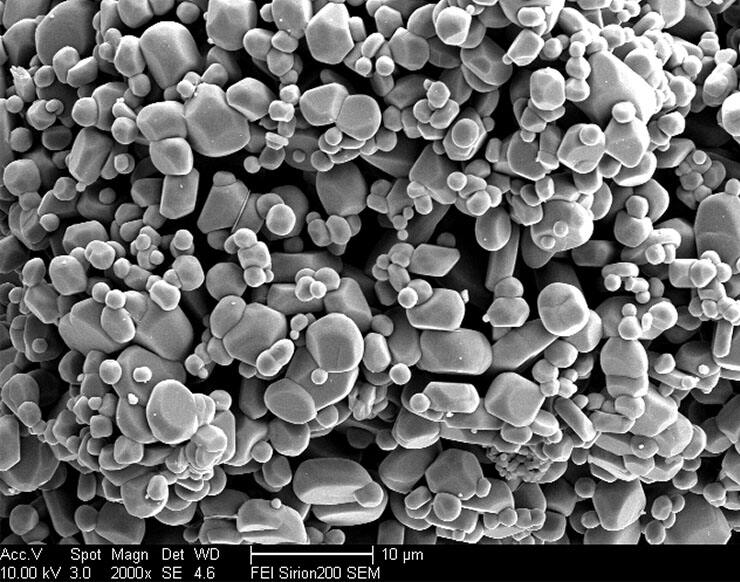

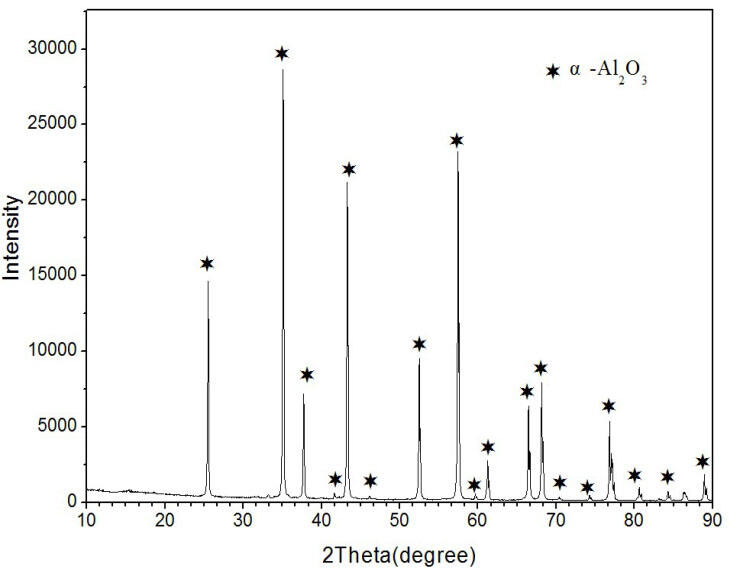

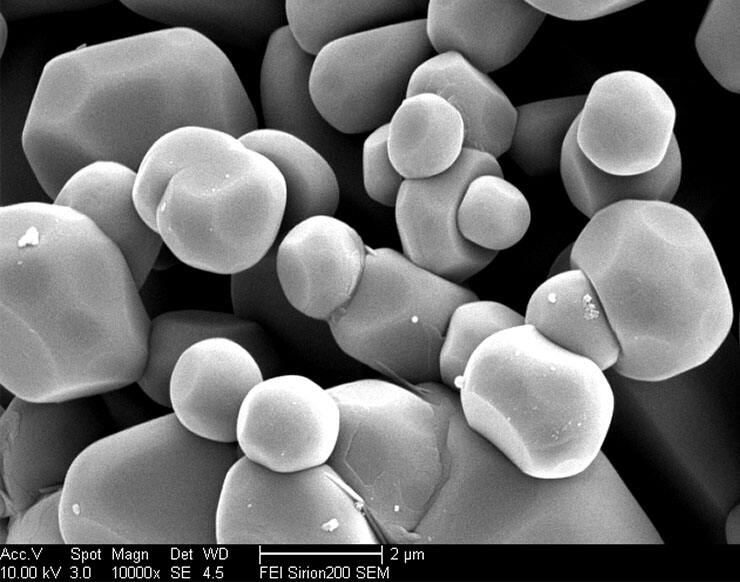

The AW series Calcined α-Al₂O₃ micro powder is the result of the national "7-5" research project. In 1990, through national identification, the technology reached the international advanced level. Calcined alumina is based on industrial aluminum hydroxide or industrial aluminum oxide as raw materials. Calcined at the appropriate temperature to produce crystalline stable a-alumina products ; Calcined alumina is made from calcined a-alumina by ball grinding. Calcined alumina generally used in shaped refractories such as sliding gate, corundum brick etc. Or with reactive alumina used in unshaped refractories.

When using calcined alumina to produce resin bonded products, its moisture is low and it is easy to mix evenly, high volume stability. When used with reactive alumina or silica powder for unshaped refractories, it can form particle gradation with finer powder to achieve the closest packing, reduce the additive amount of water and porosity, reduce rate of linear deformation and increase the strength.

Physical Properties and Chemical Composition

| Item | AW-800SG | AW-9FG | AW-4M |

| Al₂O₃(%) | 99.7 | 99.6 | 99.5 |

| SiO₂(%) | 0.10 | 0.10 | 0.10 |

| Fe₂O₃(%) | 0.03 | 0.03 | 0.04 |

| Na₂O(%) | 0.05 | 0.18 | 0.28 |

| D50(μm) | 3.5 | 4.0 | 4.5 |

Annotation:

·Particle size can also be processed according to customer requirements.

·Inspection standard:GB/T3044-2020;GB/T 24487-2022

·Packing:Inner plastic and external weaving 25KG/bag(can be customized according to customer requirements)

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ