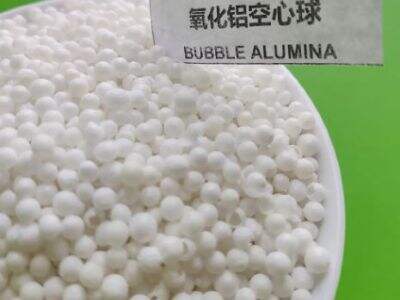

It’s exciting to see bubbles just for fun but they can be used for something as crucial as production. Bubble alumina is one kind of widely material used in industries and is obtained by heating the aluminum oxide until this forms bubbles. Currently, there are numerous company manufacturers of Bubble alumina in the UK and as a result have had to select the best three. Read on to find out more.

Advantages of Bubble Alumina

Based on the characteristics of bubble alumina by Datong, it is very suitable for being used within industries. First of all, it is light in weight and has a low thermal conductivity thus having the capacity to be used for the insulation of buildings. It also does not corrode easily and will not deform at high temperatures, ideal for processes such as chemical or petrochemical ones. Moreover, bubble alumina and Tabular alumina does not have any toxicity and, therefore, it has no harm to the environment, a crucial factor today.

Innovation in Bubble Alumina Manufacturing

With bubble alumina, the companies that manufacture the material are always in the lookout for ways through which they can enhance on the various processes and come up with the best alumina material. The accurate completion of complex tasks such as these is achieved in several of the claimed manners, including by the use of computer modeling and simulation. With these tools they can redesign the manufacturing processes for carrying out the right production of the materials with improved properties.

Safety Considerations

Reliability is one of the main factors and risks that are associated with all industrial materials and bubble alumina is not an exception. Thankfully, there are measures that the companies that manufacture bubble alumina and Brown fused alumina have in place regarding safety. Companies pay special attention to safety and provide personal protective equipment to their employees in compliance with the standards set in this area of the law. More to that, they also offer safety datasheets and other related products so that the customers can use the products safely.

Service and Quality

It has been seen that the three most preferred bubble alumina manufacturers in the UK are interested in providing not only the best quality material to its customers but also the best service possible. They know that each customer has his or her specific needs and specifications the system and they strive to understand each customer to ensure that he or she gets the right product for the intended use. Also, they provide high-quality technical assistance and the warrantee service for satisfied customers’ purchase.

Applications of Bubble Alumina

Bubble alumina used in many ways in the industrial globe. Here are just a few examples:

- Insulation: Some of the major uses of bubble alumina are in insulation as it is very light and possesses a low coefficient of thermal conduction.

- Abrasives: Thus, bubble alumina can be applied as an abrasive material due to its hardness and stability on the worked material surface.

- Catalysts: Reduced bubble alumina is applied as a support material for the catalysts of various chemical processes.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ