- Parameter

- Related products

Parameter

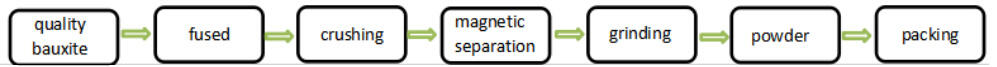

Raw material

It is made from quality bauxite, coke (anthracite) by melting in the electric arc furnace.

Advantage

1.High temperature resistance

2.Corrosion resistance

3.High hardness

| Application | Type | Size | Chemical composition(%) | |||

| Al₂O₃ | Fe₂O₃ | SiO₂ | TiO₂ | |||

| refractory | Sand | 0-1mm | 95 Min | 0.3 Max | 1.5 Max | 3.0 Max |

| 1-3mm | ||||||

| 3-5mm | ||||||

| 5-8mm | ||||||

| 8-12mm | ||||||

| Fine powder | 180 mesh | 93.5 Min | 0.5 Max | 1.5 Max | 3.5 Max | |

| 200 mesh | ||||||

| 325 mesh | ||||||

| Hardness | 9.0 mohs | |||||

| Working Temp | 1900℃ | |||||

| Melting Point | 2200℃ | |||||

| Application | Size | Chemical composition(%) | ||||

| Al₂O₃ | Fe₂O₃ | SiO₂ | TiO₂ | |||

| Abrasives | 4#-80# | ≥95 | ≤0.3 | ≤1.5 | ≤3.0 | |

| 90#-150# | ≥94 | ≤3.5 | ||||

| 180#-240# | ≥93 | ≤3.0 | ||||

| 8#-80# | ≥95 | ≤0.2 | ≤1.2 | ≤0.2 | ||

| 100#-150# | ≥94 | |||||

| 180#-220# | ≥93 | ≤0.3 | ≤1.5 | ≤3.5 | ||

| 1#-63# | ≥92.5 | ≤0.5 | ≤1.8 | ≤3.5 | ||

Applications of refractory

1. It is used to produce cast steel slide gate, lining (wall and tube) of smelting rare metal, special alloys, ceramics, iron blast furnace, spark plug, heat resistant and oxidation resistant coating.

2. Corundum insulation materials, such as corundum lightweight bricks, corundum bubble alumina bricks and fiber products, it is widely used in furnace walls and furnace roofs of various high-temperature furnaces, which are resistant to high temperature and heat preservation.

Application of abrasives

1. Grinding metal, such as a variety of common steel, malleable iron and hard bronze, etc.

2. Grinding media, sandblasting media; surface cleaning, sandblasting, polishing, grinding, etching, wet and dry blasting, mineral skin abrasion materials.

3. Metal finishing & surface preparation, ceramics, coatings, bonded & coated abrasives.

Packing

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ