Cement suppliers high alumina Refractory cement white cement

- WhatsApp: +86 13781152999

- E-mail: [email protected]

- Parameter

- Related products

Parameter

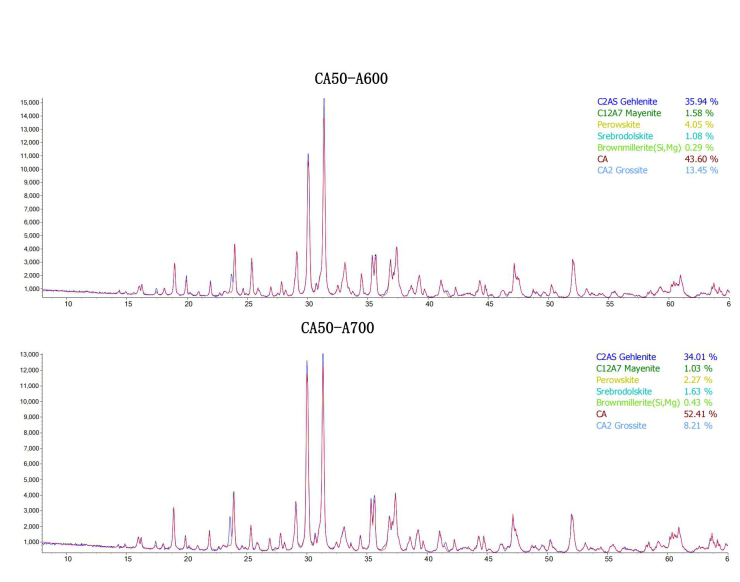

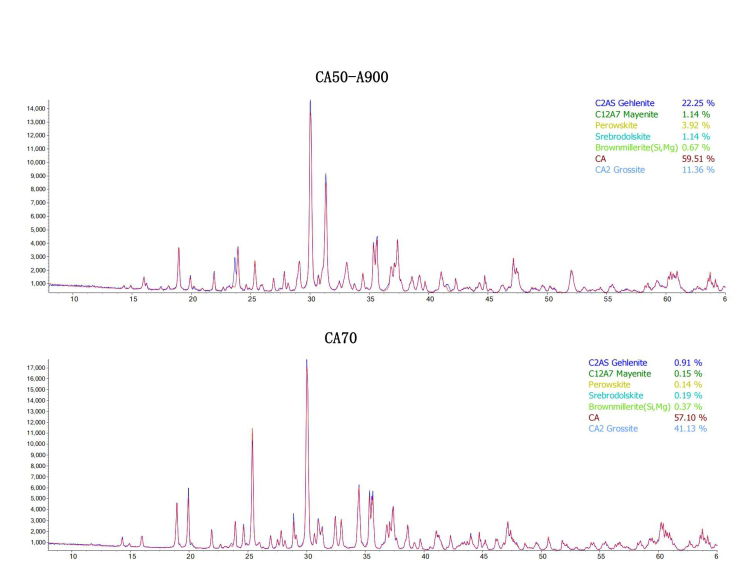

The high alumina cement A600 has rapid setting and hardening characteristics,and is mainly used to prepare traditional medium -high class cement castable,such as alkaline-resistant castable, ordinary high alumina castable, and skimming ball production. The high alumina cement A700 uses high -quality raw material production, which has low impurities content; stable condensation and hardening performance, with fast intensity development and excellent mechanical strength; widely used in medium and low cement castable, construction performance and high temperature performance better. The high alumina cement A900 is made of special grade bauxite and high purity limestone, with high alumina content, very low impurities content, stable setting and hardening performance, with good fluidity, excellent workability, rapid strength development and ultra-high mechanical strength, excellent high temperature resistance. It is widely used in the preparation of low cement and ultra-low cement castable.

Physical Properties and Chemical Composition

| Performance index | A600 | A700 | A900 | |

| Chemical composition(%) | Al₂O₃ | ≥50 | ≥50 | ≥53 |

| SiO₂ | ≤9.0 | ≤8.0 | ≤6.0 | |

| Fe₂O₃ | ≤3.0 | ≤3.0 | ≤3.0 | |

| R₂O | ≤0.5 | ≤0.5 | ≤0.5 | |

| S- | ≤0.2 | ≤0.2 | ≤0.2 | |

| CΓ | ≤0.06 | ≤0.06 | ≤0.06 | |

| BET(cm/g) | ≥320 | ≥350 | ≥380 | |

| 325mesh screen residue (%) | ≤20 | ≤15 | ≤8 | |

| Setting time | Initial Set (min ) | ≥30 | ≥30 | ≥150 |

| Final Set (h) | ≤360 | ≤360 | ≤360 | |

| CCS/CMOR(MPa) | 1d | ≥40/5.5 | ≥50/6.5 | ≥70/8.5 |

| 3d | ≥50/6.5 | ≥60/7.5 | ≥80/9.5 | |

| Inspection standard | Chemical composition : GB/T 205 ; B.E.T. : GB/T8074;Setting time : GB/T 1346 ; Strength : GB/T17671 & GB201-2000 | |||

| Packing | Inner plastic and external weaving 25KG/bag(can be customized according to customer requirements) | |||

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ