- Parameter

- Related products

Parameter

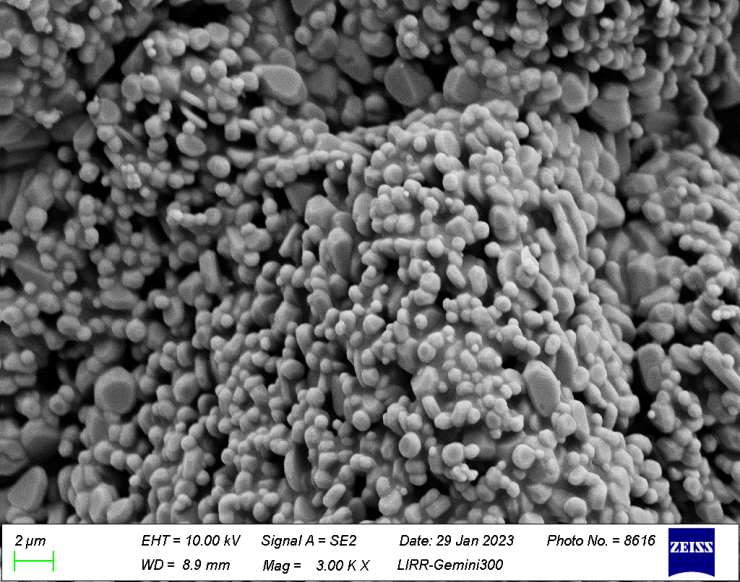

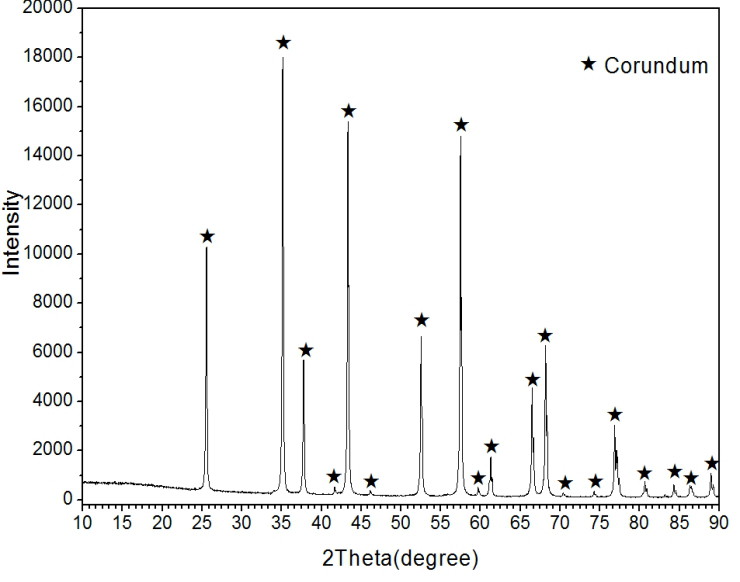

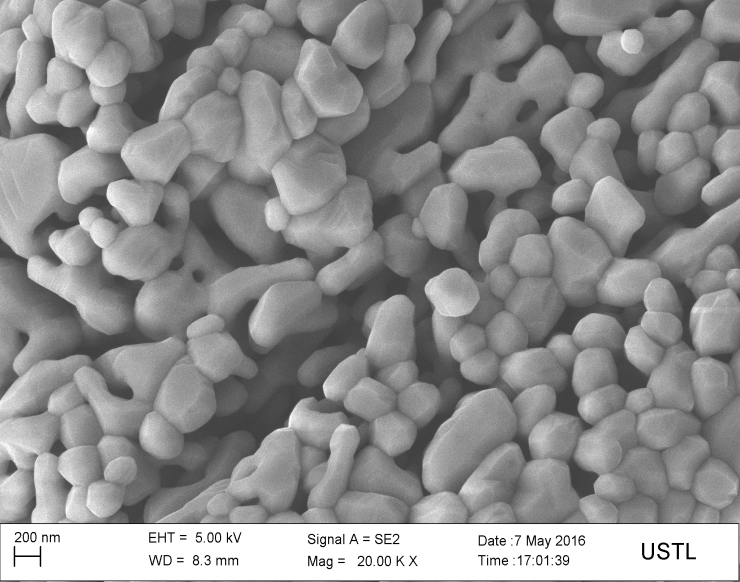

Our company's AW series active α-Al₂O₃ micro powder is a result of the national "Eighth Five Year Plan" research and development project. It passed the national appraisal in 1994 and has reached the international advanced level of technology. Its unique process fully endows the product with the characteristics of high activity, small grain size, and high phase conversion rate, making it an important raw material for producing high-quality refractory materials. The product is selected and produced by large refractory material enterprises and research institutes, including key products such as ladle castables, iron groove castables, permeable bricks, seat bricks, corundum self flowing castables, spray coatings, skateboards, magnesia carbon bricks, lithium battery box bowls, etc. The use effect is no different from similar products in Europe and America. It is also exported to famous refractory material production enterprises in Japan, the United States, Europe, Russia, and Southeast Asia.

Our company's AW series α-Al₂O₃ micro powder, based on the establishment of a micro powder particle size control model, effectively controls and optimizes the particle size distribution of the micro powder. At the same time, special additives are used for phase transformation and surface modification, making our alumina micro powder have low impurity content, fine particle size, reasonable particle size distribution, controllable activity, good flowability, low swelling, long working time, high medium temperature strength, dense structure, and good use effect in castables.

Physical Properties and Chemical Composition

|

Model(typical) |

AW-12M | AW-12L | AW-06L | AW-SF | Compound powder |

| Al₂O₃(%) | 99.50 | 99.60 | 99.60 | 99.08 | 99.51 |

| SiO₂(%) | 0.12 | 0.12 | 0.11 | 0.10 | 0.09 |

| Fe₂O₃(%) | 0.08 | 0.08 | 0.08 | 0.13 | 0.04 |

| Na₂O(%) | 0.18 | 0.04 | 0.04 | 0.13 | 0.12 |

| D50(μm) | 1.90 | 1.85 | 0.95 | 2.5 | 2.87 |

| α-AL₂O₃%Conversion rate | 95 | 95 | 95 | 95 | 95 |

| Grain Size Distribution | Mono-modal | Mono-modal | Mono-modal | Bi-modal | Multi-modal |

note:

·Particle size can also be processed according to customer requirements.

·Test standard:GB/T3044-89;GB3604-83

·Package:Inner plastic outer braid 25kg/bag or 1000KG/bag(as customers' requirement)

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ