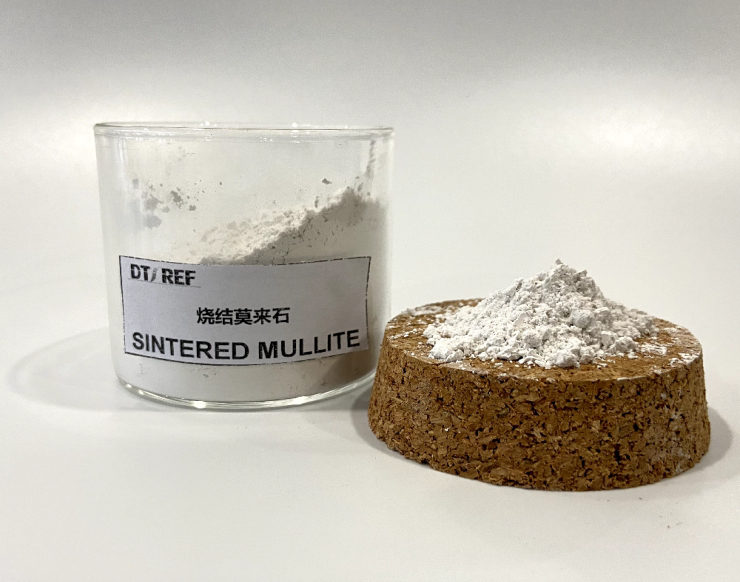

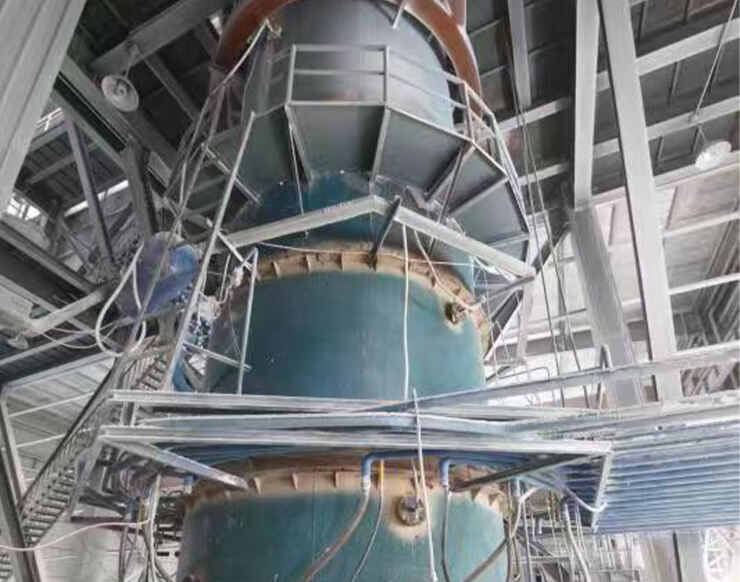

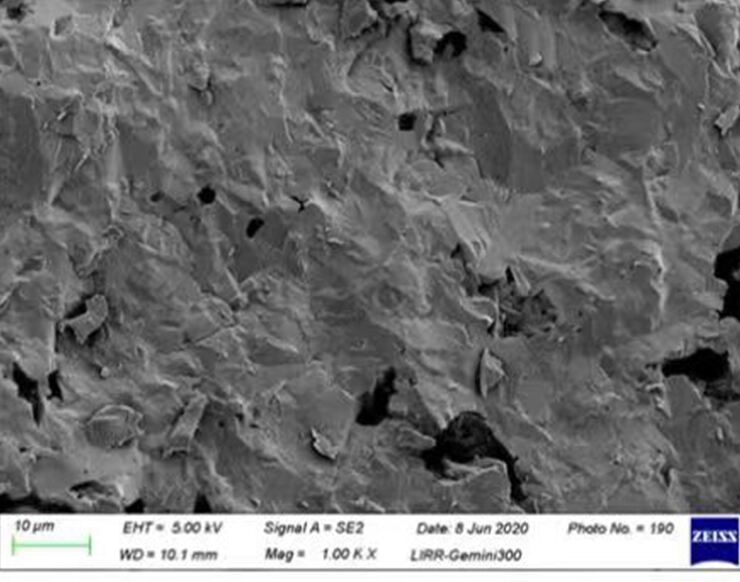

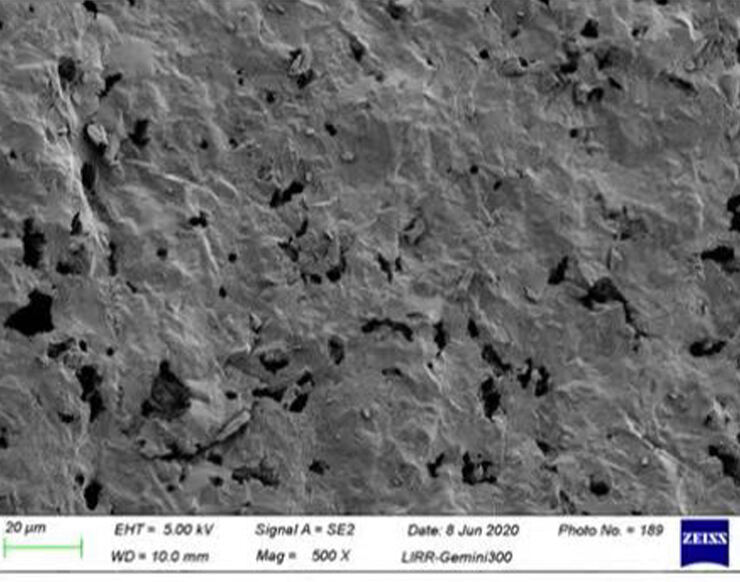

Sintered mullite is made of high purity raw materials such as industrial alumina and kaolin by ultra-fine grinding, forming and sintering at high temperature by shaft kiln. The product has the characteristics of high purity, good crystal development,uniform expansion, good thermal shock stability, high softening point under load,low creep at high temperature, good chemical stability, etc. lt is the ideal raw material for refractory materials in iron and steel metallurgy, ceramics, building materials, chemical industry, casting and other industries. According to the alumina content mulite is classified into SAS-75,SAS-70SAS-60.

Fysiske egenskaber og kemisk sammensætning

| Item/Component |

AL203 |

SiO2 |

Na₂O+K₂O |

Fe203 |

TiO2 |

Bulk density(g/cm) |

| SAS-75 |

≥75 |

21 ~ 24 |

≤ 0.40 |

≤ 0.50 |

≤ 0.40 |

≥2.85 |

| SAS-70 |

70 ~ 73 |

26 ~ 29 |

≤ 0.40 |

≤ 0.50 |

≤ 0.45 |

≥2.80 |

| SAS-60 |

58 ~ 62 |

37 ~ 41 |

≤ 0.40 |

≤ 0.50 |

≤ 0.50 |

≥2.7 |

| Partikelstørrelse |

0~0.5~1~3~5~8~15mm,100 mesh、200mesh、325 mesh,5μm,3μm |

| Inspektionsstandard |

GB5069-2001 |

| Pakning |

Indvendig plastik og ekstern vævning 25KG/pose (kan tilpasses efter kundens krav) |

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO INGEN

INGEN PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ