Fire resistance calcium aluminate high aluminate cement/Refractory Cement High Alumina Mortar For Furnace Fire Bricks

- WhatsApp: +86 13781152999

- E-mail: [email protected]

- Parameter

- Related products

Parameter

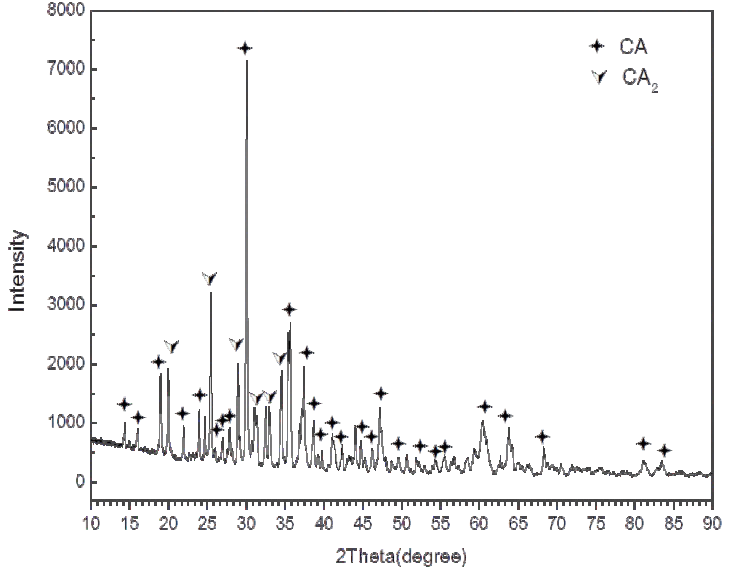

DianKa@ use industrial aluminum oxide and high-purity limestone as raw materials, cement is produced through arc furnace melting, smelting, and cooling process, and then finely ground and homogenized into finished products. DianKa@ series fused pure calcium aluminate cement has excellent early strength, wide application range, stable setting time and other characteristics. DianKa@ series cement gives priority to the practical application needs of customers, so that it has been targeted in the setting time, flowability, strength, particle size distribution and chemical composition composition. It makes it the preferred brand of refractory castable manufacturers at home and abroad.

In addition to the inspection in accordance with the GB/T 205 standard content before the DianKa@ cement leaves the factory, it highlights the actual castable application performance testing, including pure corundum castable without silica fume, high alumina castables containing silica fume application performance test (5% cement dosage), and can also carry out castables application performance tests according to customer requirements and operating environment, and mark the relevant index data in the factory quality certificate to help customers get better user experience.

Physical Properties and Chemical Composition

| Parameter | DK-68 | DK-71 | DK-80 | DK-90 | |

| Chemical composition(%) | Al₂O₃ | ≥64 | ≥68 | ≥78 | ≥60 |

| CaO | ≤35 | ≤31 | ≤21 | ≤39 | |

| SiO₂ | ≤0.4 | ≤0.4 | ≤0.3 | ≤0.6 | |

| Fe₂O₃ | ≤0.4 | ≤0.4 | ≤0.3 | ≤0.5 | |

| BET(cm/g) | ≥4500 | ≥4500 | ≥6000 | ≥4500 | |

| 0.045mmScreen residue (%) | ≤15 | ≤10 | ≤15 | ||

| Setting time | Initial setting time(min) | ≥30 | ≥20 | ||

| Final setting time (h) | ≤6 | ≤5 | |||

| CCS/CMOR(MPa) | Maintenace 6h | ≥10/2 | ≥8/1.5 | ≥15/3 | |

| Maintenace 24h | ≥40/6 | ≥40/5 | ≥55/8 | ||

| Inspection standards | Chemical composition : GB/T 205;BET :GB/T8074;Setting time : GB/T 1346; CCS/CMOR : GB/T17671 & GB201-2000 | ||||

| Packing | Inner plastic and external weaving 25KG/bag(can be customized according to customer requirements) | ||||

①DK-68:Mainly used in ordinary alumina-silica castable, excellent early strength performance and ultra-high cost performance, making it the first choice in medium and high temperature environents;

②DK-71:General-purposē high-performance aluminate binder, widely used in various monoithic (unshaped) refractories, such as vibrating castable, gunning, self-flowing, ramming mixes andso on;

③DK-80:Easy-to-use aluminate binder products that can be adapted to customer needs for customer convenience. Thisproduct is mainly used in castables which are sensitive to calcium oxide content;

④DK-90:It is a product with 90% CA ore phase ,mainly used in the special castables and prefabricated which are: less cement addition (calcium oxide reduction), better early strength, prefabricates request rapid demolding.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ