SEMUA PRODUK

-

Zirkonia

-

silica

-

Alumina leburan berwarna coklat

-

Kaolin

-

Bauksit

-

Mullite yang disinter

-

Mullite menyatu

-

Semen alumina tinggi seri CA50

-

Gelembung Alumina

-

Alumina Tabular

-

Alumina Lebur Putih

-

Semen kalsium aluminat

-

Spinel alumina magnesia yang disinter

-

Spinel alumina magnesia menyatu

-

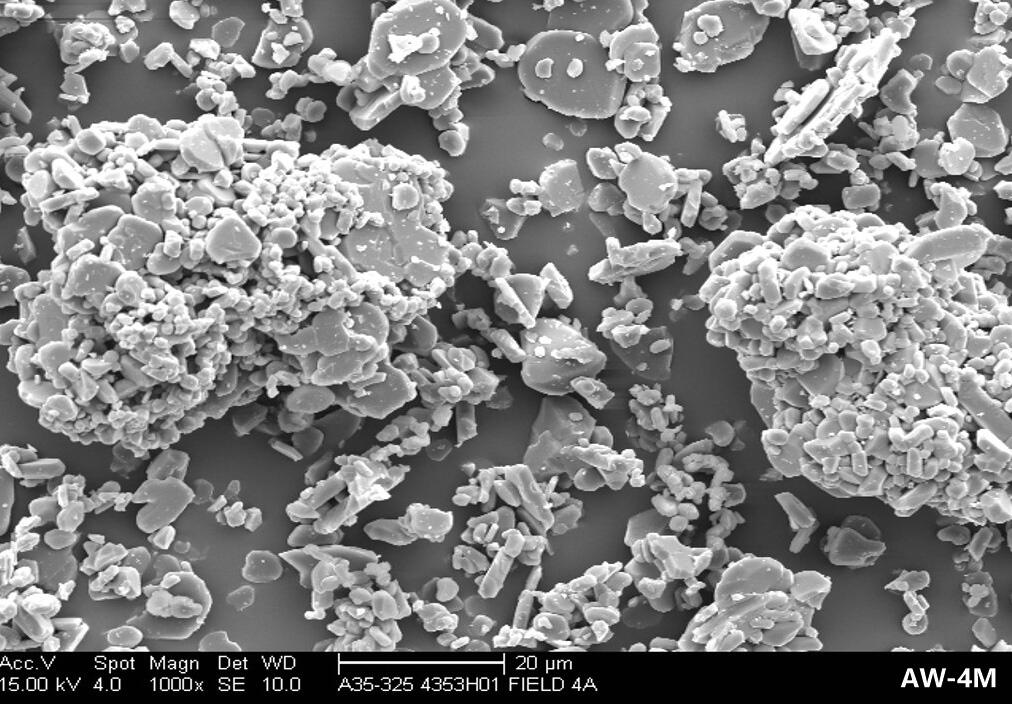

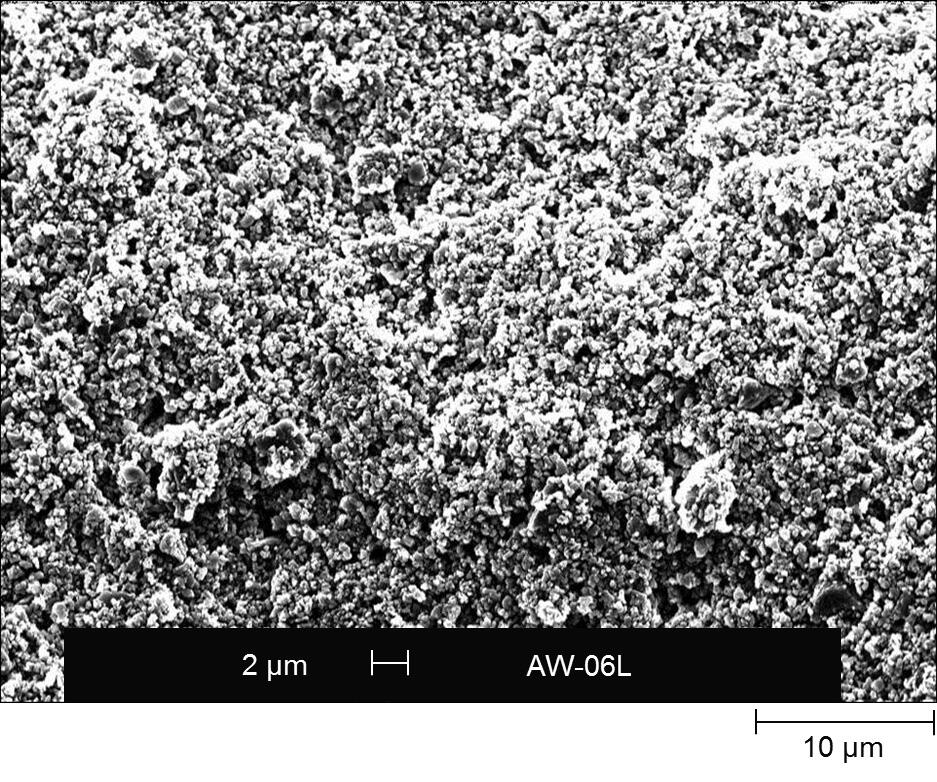

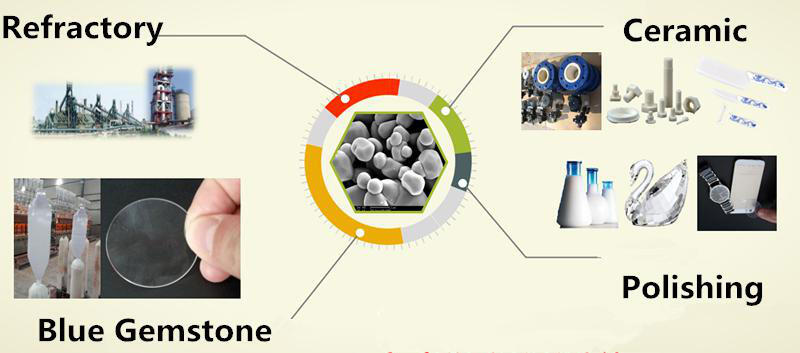

Bubuk α-AL₂O₃ yang dikalsinasi

-

Serbuk α-AL₂O₃ Reaktif

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO TIDAK

TIDAK PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ