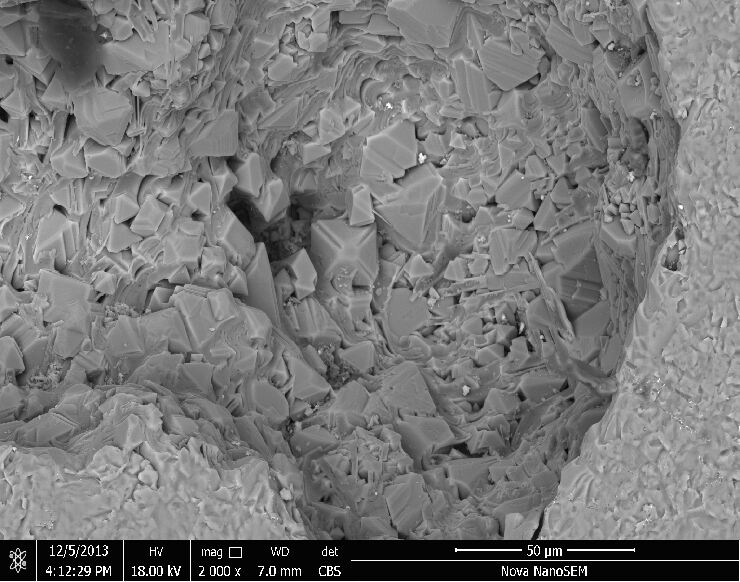

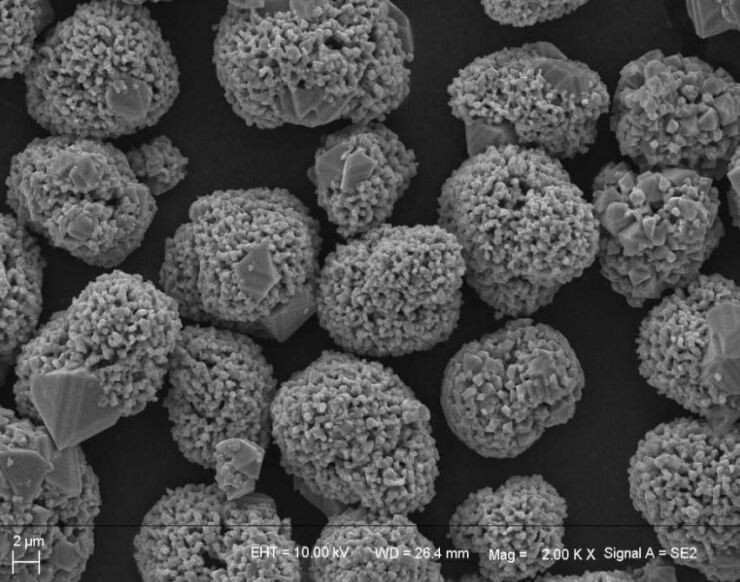

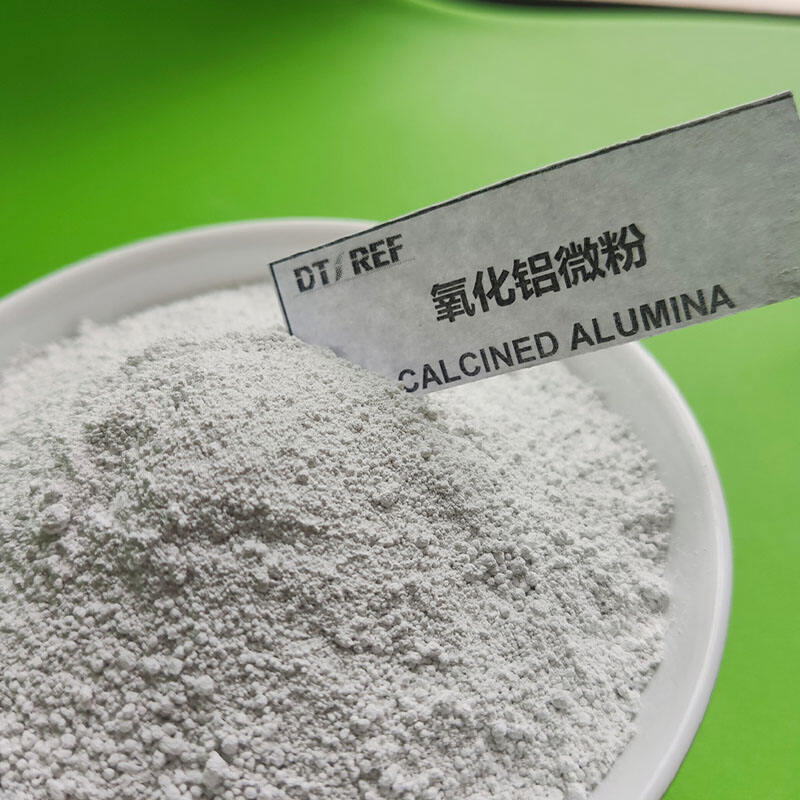

"Jun" brand sintered alumina-magnesia spinel is based on industrial alumina and dead burnt magnesite, through the multi-stage homogenization process,sintered in ultra-high temperature shaft kiln, with large volume density, high spinel phase content, good crystal development, uniform structure, stable performance. Also alumina-magnesia spinel has corrosion resistance, peeling resistance, good slag resistance, good thermal shock stability, high temperature resistance and other characteristics.

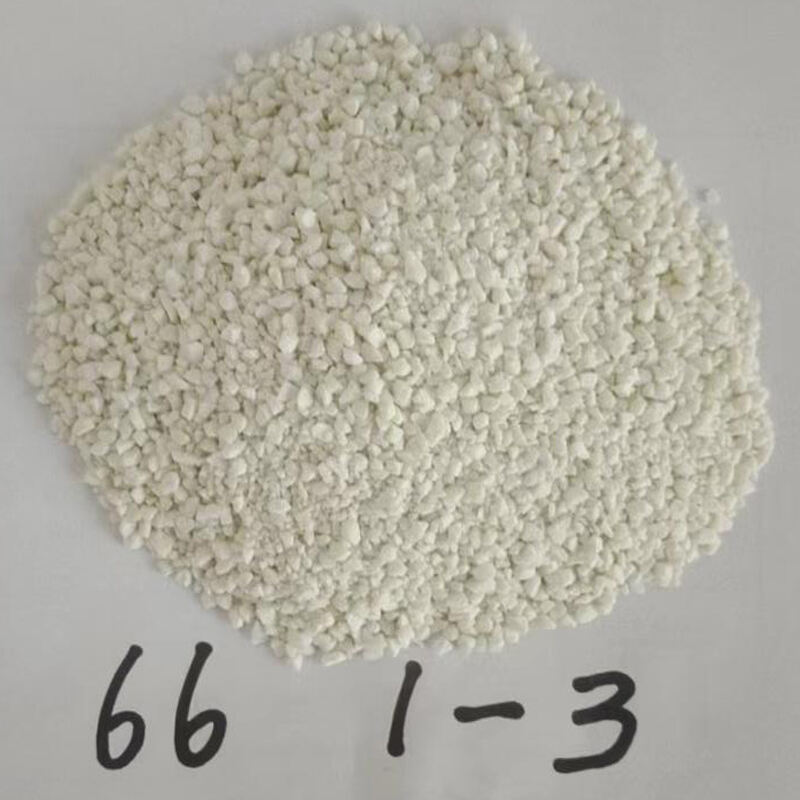

High quality sintered alumina-magnesia spinel provide guarantee for the production ofshaped and unshaped high -performance refractory materials. lt is an ideal raw material for fire-resistant products such as magnesia-alumina spinel brick for cement rotary kiln, ladle brick, and refractory carstables for ladles. On steel metallurgical, cement rotary kiln and glass industrial kiln.According to alumina content, sintered magnesia-alumina spinel is classified into SAM-50SAM-66,SAM-78 and SAM-90 varieties.

Właściwości fizyczne i skład chemiczny

| Przedmiot/komponent |

AL₂O₃ |

MgO |

CaO |

SiO₂ |

Fe₂O₂ |

Na₂O |

Bulk density(g/c㎡) |

| SAM-50 |

48 ~ 52 |

46 ~ 50 |

≤ 0.60 |

≤ 0.45 |

≤ 0.35 |

≤ 0.25 |

≥3.2 |

| SAM-66 |

64 ~ 68 |

32 ~ 36 |

≤ 0.50 |

≤ 0.35 |

≤ 0.30 |

≤ 0.30 |

≥3.2 |

| SAM-78 |

76 ~ 79 |

20 ~ 24 |

≤ 0.40 |

≤ 0.30 |

≤ 0.25 |

≤ 0.35 |

≥3.2 |

| SAM-90 |

89 ~ 92 |

8 ~ 11 |

≤ 0.30 |

≤ 0.25 |

≤ 0.20 |

≤ 0.35 |

≥3.3 |

| Rozmiar cząsteczki |

0~0.2~0.5~1~2~3~5~8mm,100 mesh、200 mesh、325 mesh,5μm,3μm. |

| Standard inspekcji |

GB5069-2001 |

| Uszczelka |

Wewnętrzny plastik i splot zewnętrzny 25 kg/worek (można dostosować do wymagań klienta) |

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NIE

NIE PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ