Sintered Alumina Magnesia Spinel with Good Grain Development

- WhatsApp: +86 13781152999

- E-mail: [email protected]

- Parameter

- Related products

Parameter

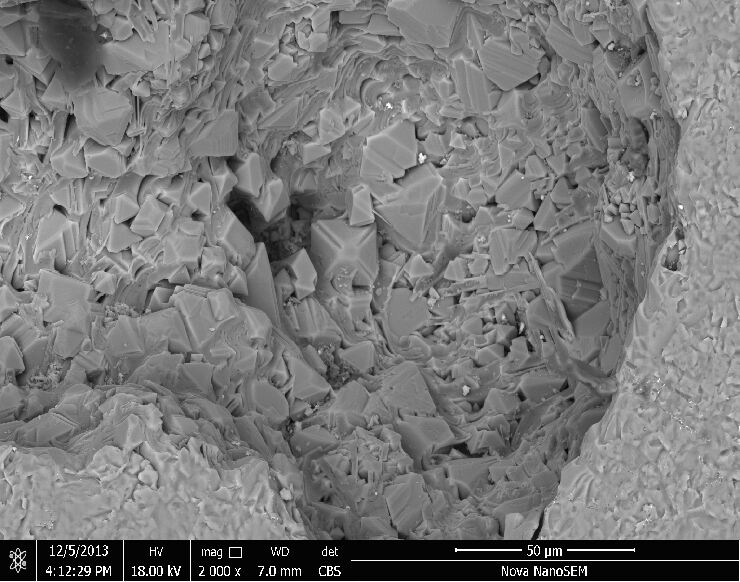

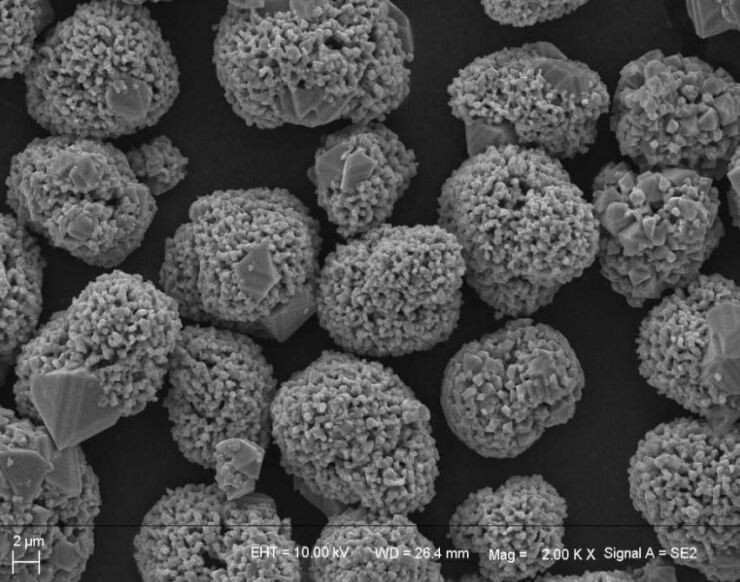

"Jun" brand sintered alumina-magnesia spinel is based on industrial alumina and dead burnt magnesite, through the multi-stage homogenization process,sintered in ultra-high temperature shaft kiln, with large volume density, high spinel phase content, good crystal development, uniform structure, stable performance. Also alumina-magnesia spinel has corrosion resistance, peeling resistance, good slag resistance, good thermal shock stability, high temperature resistance and other characteristics.

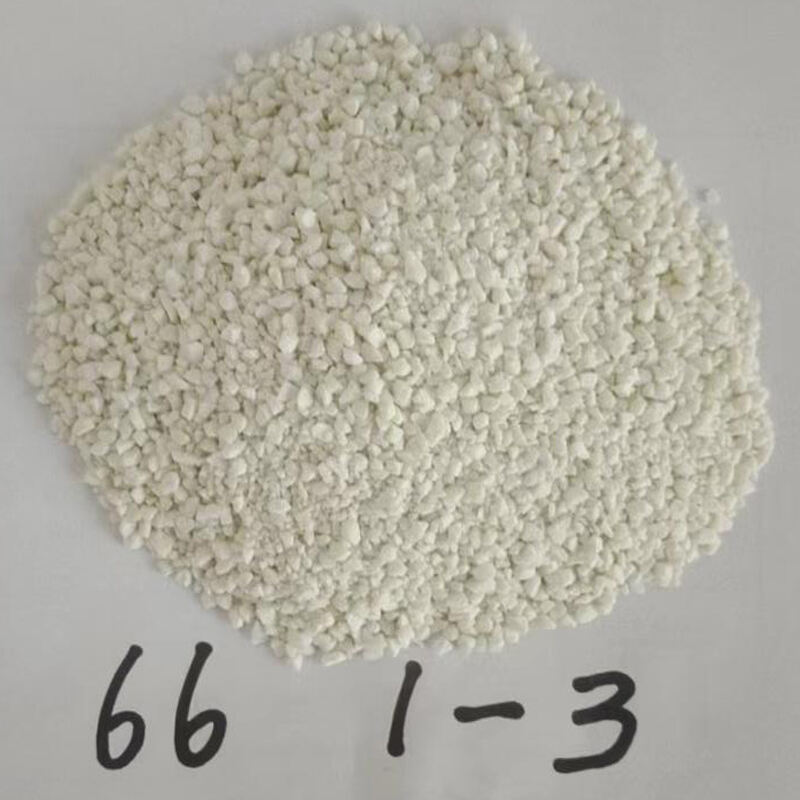

High quality sintered alumina-magnesia spinel provide guarantee for the production ofshaped and unshaped high -performance refractory materials. lt is an ideal raw material for fire-resistant products such as magnesia-alumina spinel brick for cement rotary kiln, ladle brick, and refractory carstables for ladles. On steel metallurgical, cement rotary kiln and glass industrial kiln.According to alumina content, sintered magnesia-alumina spinel is classified into SAM-50SAM-66,SAM-78 and SAM-90 varieties.

Physical Properties and Chemical Composition

| Item/Component | Al₂O₃ | MgO | CaO | SiO₂ | Fe₂O₂ | Na₂O | Bulk density(g/c㎡) |

| SAM-50 | 48~52 | 46~50 | ≤0.60 | ≤0.45 | ≤0.35 | ≤0.25 | ≥3.2 |

| SAM-66 | 64~68 | 32~36 | ≤0.50 | ≤0.35 | ≤0.30 | ≤0.30 | ≥3.2 |

| SAM-78 | 76~79 | 20~24 | ≤0.40 | ≤0.30 | ≤0.25 | ≤0.35 | ≥3.2 |

| SAM-90 | 89~92 | 8~11 | ≤0.30 | ≤0.25 | ≤0.20 | ≤0.35 | ≥3.3 |

| Particle size | 0~0.2~0.5~1~2~3~5~8mm,100 mesh、200 mesh、325 mesh,5μm,3μm. | ||||||

| Inspection standard | GB5069-2001 | ||||||

| Packing | Inner plastic and external weaving 25KG/bag(can be customized according to customer requirements) | ||||||

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ