- Parameter

- Related products

Parameter

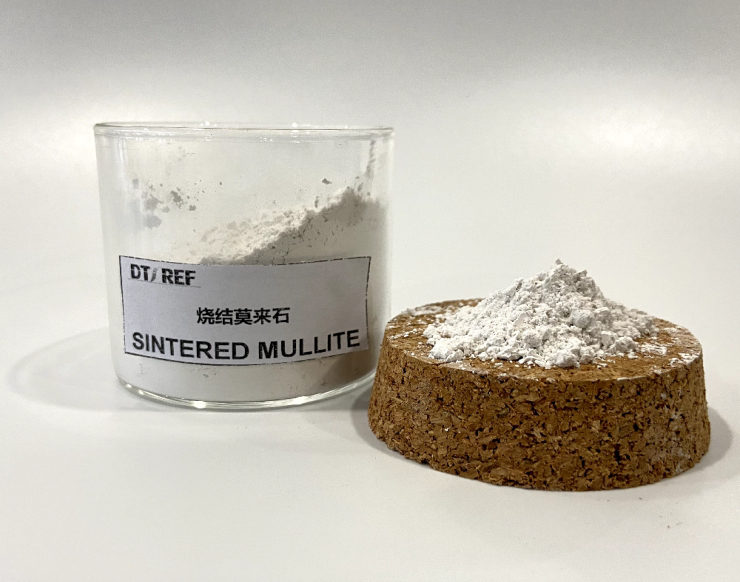

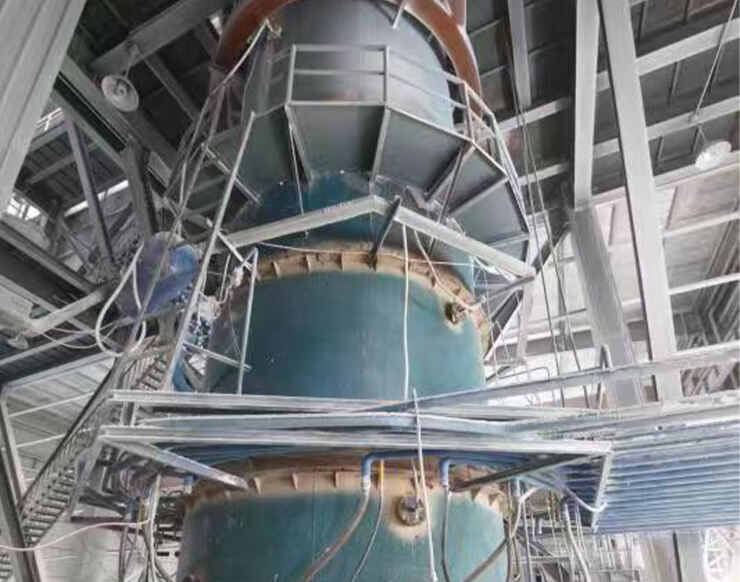

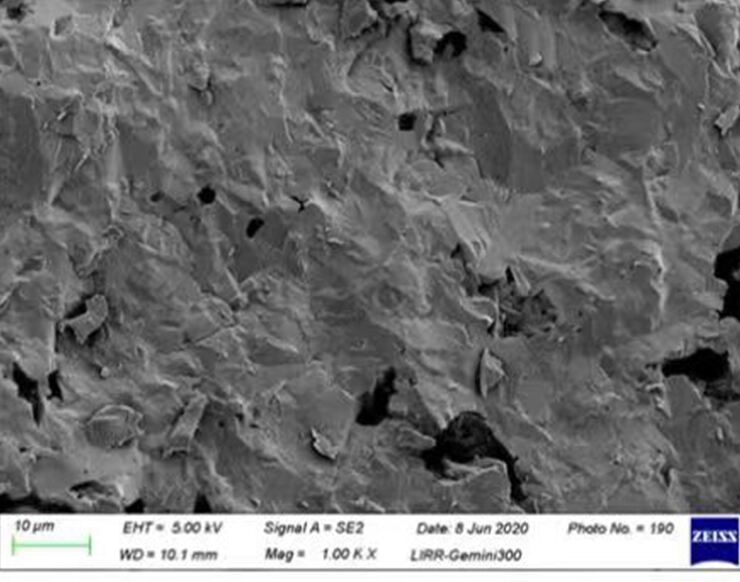

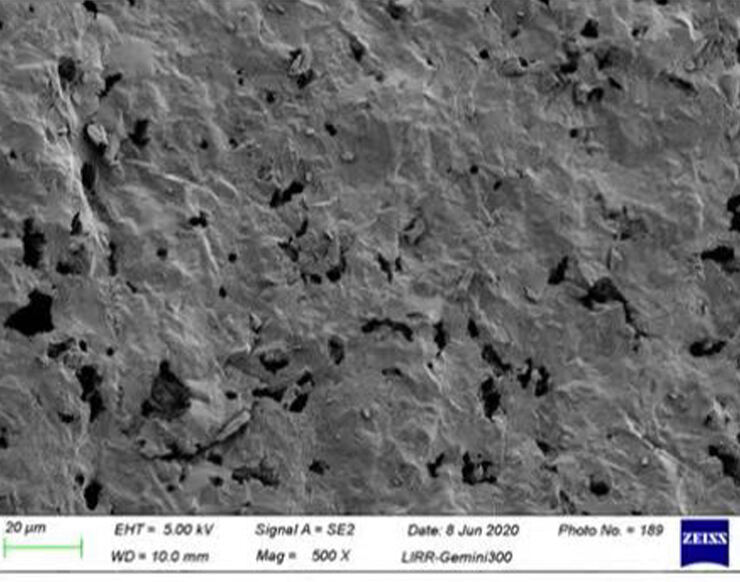

Sintered mullite is made of high purity raw materials such as industrial alumina and kaolin by ultra-fine grinding, forming and sintering at high temperature by shaft kiln. The product has the characteristics of high purity, good crystal development,uniform expansion, good thermal shock stability, high softening point under load,low creep at high temperature, good chemical stability, etc. lt is the ideal raw material for refractory materials in iron and steel metallurgy, ceramics, building materials, chemical industry, casting and other industries. According to the alumina content mulite is classified into SAS-75,SAS-70SAS-60.

Physical Properties and Chemical Composition

|

Item/Component |

Al₂O₃ | SiO₂ | Na₂O+K₂O | Fe₂O₃ | TiO₂ | Bulk density(g/cm) |

| SAS-75 | ≥75 | 21~24 | ≤0.40 | ≤0.50 | ≤0.40 | ≥2.85 |

| SAS-70 | 70~73 | 26~29 | ≤0.40 | ≤0.50 | ≤0.45 | ≥2.80 |

| SAS-60 | 58~62 | 37~41 | ≤0.40 | ≤0.50 | ≤0.50 | ≥2.7 |

| Particle size | 0~0.5~1~3~5~8~15mm,100 mesh、200mesh、325 mesh,5μm,3μm | |||||

| Inspection Standard | GB5069-2001 | |||||

| Packing | Inner plastic and external weaving 25KG/bag(can be customized according to customer requirements) | |||||

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ