The "Iun notam alte-puram aluminam magnesiam spinelam fusam uti alta magnesia -pura et alumina industrialis excoquunt per magnas fornaces electrici arcus-temperature.

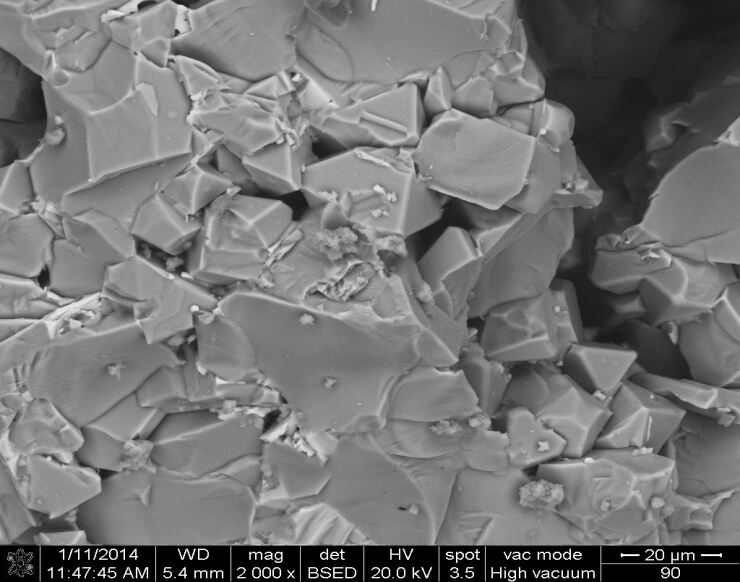

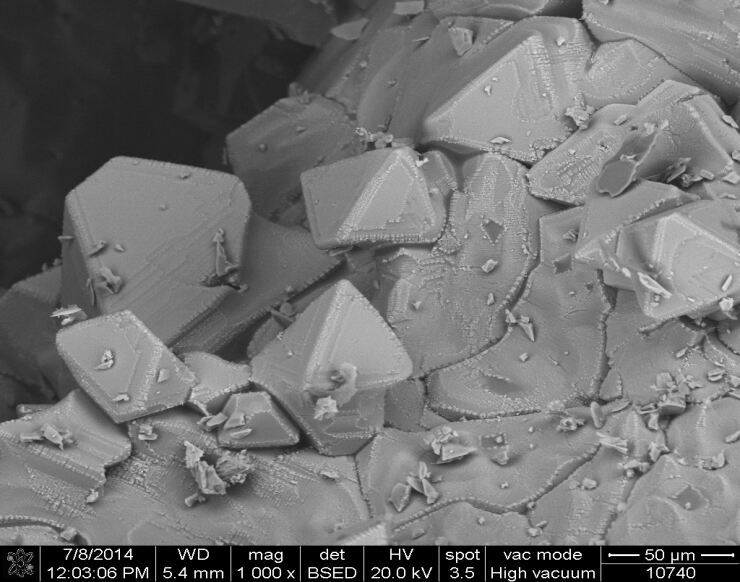

The "Jun brand high-pure fused alumina magnesia spinel use high -pure magnesia and industrial alumina smelting by large high -temperature electric arc furnaces. lt has high density, high refractory resistance, and good hightemperature volume stability, anti alkaline slag erosion and permeability, good thermal stability and other characteristics. lt is widely used for steelmaking electric

furnace top, converter, ladle and porous plug brick/ladle well block, RH spinel brick/back lining castable, tundish current stabilizer & impacting plate board,transition zone of large cement rotary kiln & burnning zone, smelting alloy and glass heat storage rooms, lithium battery saggar and special plasma spray coatings.

Alumina -magnesia spinae in castella refractoria introducens signanter liquido, anti penetratione, anti-erosione et anti-pepeculatione castabilium persecutio emendare potest. Praesertim, facultatem anti lavandi emendare potest, vitam operariam emendare, materiam refractoriam ad productionem per ton ferream requisitam minuere. Etiam problema solvendum materiae crepuit addendo magnesiam materiae rudis.

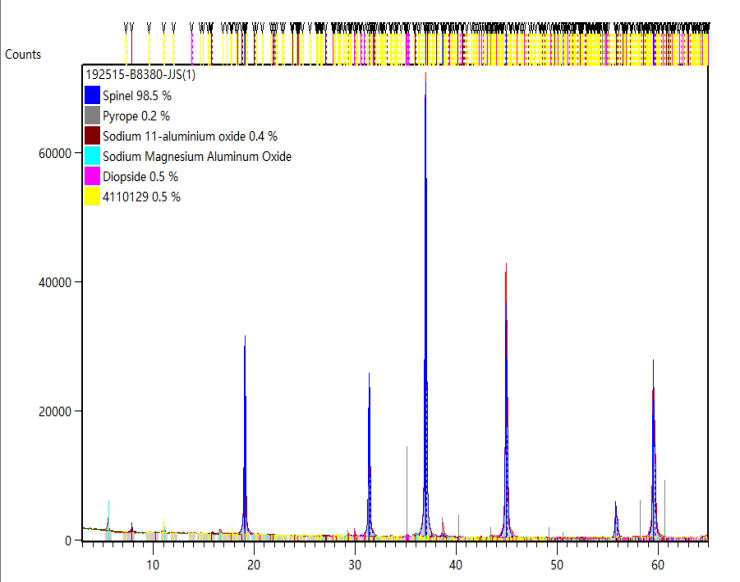

Corporalia proprietates et chemica compositio

| Item / Compositio | AL₂O₃ | MgO | CAO | SiO₂ | Fe₂O₃ | Na₂O | Mole densitatis (g/cm) |

| AM-65 | 64 ~ 66 | 33 ~ 35 | ≤0.65 | ≤0.50 | ≤0.40 | ≤0.30 | ≥3.3 |

| AM-70 | 74 ~ 76 | 23 ~ 25 | ≤0.55 | ≤0.40 | ≤0.40 | ≤0.30 | ≥3.2 |

| AM-90 | 87 ~ 90 | 9 ~ 12 | ≤0.30 | ≤0.25 | ≤0.30 | ≤0.40 | ≥3.3 |

| particula magnitudine | 0~0.2~0.5~1~2~3~5~8mm,100 mesh、200 mesh、325 mesh、5μm | ||||||

| speculationis stndard | GB5069 2001, | ||||||

| sarcina | Interna plastica et externa textura 25KG/peram (potest nativus secundum mos requisita)) | ||||||