Tabular alumina is a pure, no additives such as MgO, B₂O₃and other additives and ultra-high temperature sintering shrinkage of sintered a-alumina material. Tabular alumina has a fully developed hexagonal lamellar crystal structure of approximately 20...

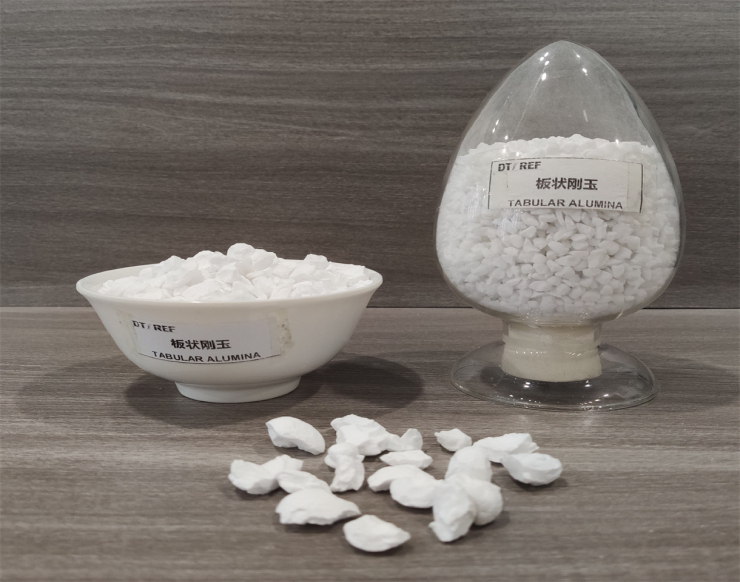

Tabular alumina is a pure, no additives such as MgO, B₂O₃and other additives and ultra-high temperature sintering shrinkage of sintered a-alumina material. Tabular alumina has a fully developed hexagonal lamellar crystal structure of approximately 200ym.lt has coarse crystal, more closed pores and small pores in the crystal, so it has excellent thermal volume stability and thermal shock resistance. Tabular alumina has AL₂O₃ 99% min high chemical purity, so it has excellent insulation characteristics.extremely high heat resistance, mechanica strength and wear resistance, acid and alkali corrosion resistance.

Tabular alumina is a key basic raw material for the production of high-quality unshaped and shaped refractories. Widely used in steel, casting, petrochemical.ceramic/special ceramics, abrasives and incineration and other industries. And other applications include electrical insulators, kiln appliances, rollers and catalyst carriers. Tabular aluminar is an excellent product for use as a filler for epoxy resins or resin systems with which the desired high insulation strength, thermal conductivity and wear resistance can be obtained.

Physical Properties and Chemical Composition

| Item | Aggregate | Fine | |||

| specification | Typical lalue | specification | Typical Value | ||

| Chemical composition(%) | Al₂O₃ | ≥99.5 | 99.52 | ≥99.3 | 99.50 |

| SiO₂ | ≤0.09 | 0.02 | ≤0.15 | 0.05 | |

| Na₂O | ≤0.40 | 0.36 | ≤0.40 | 0.38 | |

| Fe(magnetic) | ≤0.02 | 0.005 | ≤0.02 | 0.015 | |

| Physical Properties | Buk Densty (gtm) | ≥3.50 | 3.6 | ||

| Apparent Porosty (%) | ≤5 | 2.5 | |||

| Water Absoption(%) | ≤1.5 | 0.7 | |||

| 1)AL2O,subtraction method :2) The bulk density is generally 6-3mm as the standard ;3 ) Tabular alumina according to Chinese standardsYB/T4216-2010 | |||||

Particle size distribution

| Particle size distribution | |||

| specification (mm) | Min to Max (%) | Typical Value (%) | |

| 10-5 | +10 | 0~20 | 5 |

| +6.3 | 45~85 | 75 | |

| -4 | 0~5 | 1 | |

| 6-3 | +6.3 | 0~5 | 1 |

| +4 | 25~55 | 40 | |

| -3.35 | 0~5 | 1 | |

| 3-1 | +3.35 | 0~10 | 4 |

| +2 | 30~80 | 55 | |

| -1 | 0~10 | 2 | |

| 1-0 | +1 | 1~30 | 10 |

| +0.5 | 15~60 | 36 | |

| -0.106 | 5~25 | 12 | |

| 325 Mesh-0 | +0.045 | 0~5 | 2 |

| -0.045 | 95~100 | 98 | |